Strategic supply chain redesign in an era of trade volatility

What issue can we solve for you?

Type in your prompt above or try one of these suggestions

Suggested Prompt

The Hidden Tariff Tax: Why Your Supply Chain Needs a Battle Plan Now

- Flexible supply networks reduce costs fast: Companies with factories and suppliers spread across multiple regions can quickly shift production when tariffs hit. This helps them avoid surprise cost spikes—and keep prices and delivery times stable—while competitors scramble to adjust.

- Scenario planning helps you stay ready: Businesses that prepare for different tariff scenarios in advance, and build cost-sharing terms into supplier contracts, can keep operations running smoothly even when trade policies suddenly change.

- Predictive analytics prevent inventory waste: Companies that use forecasting tools to model how tariffs will affect customer demand can avoid having too much or too little inventory. By adjusting production early, they protect service levels and free up working capital.

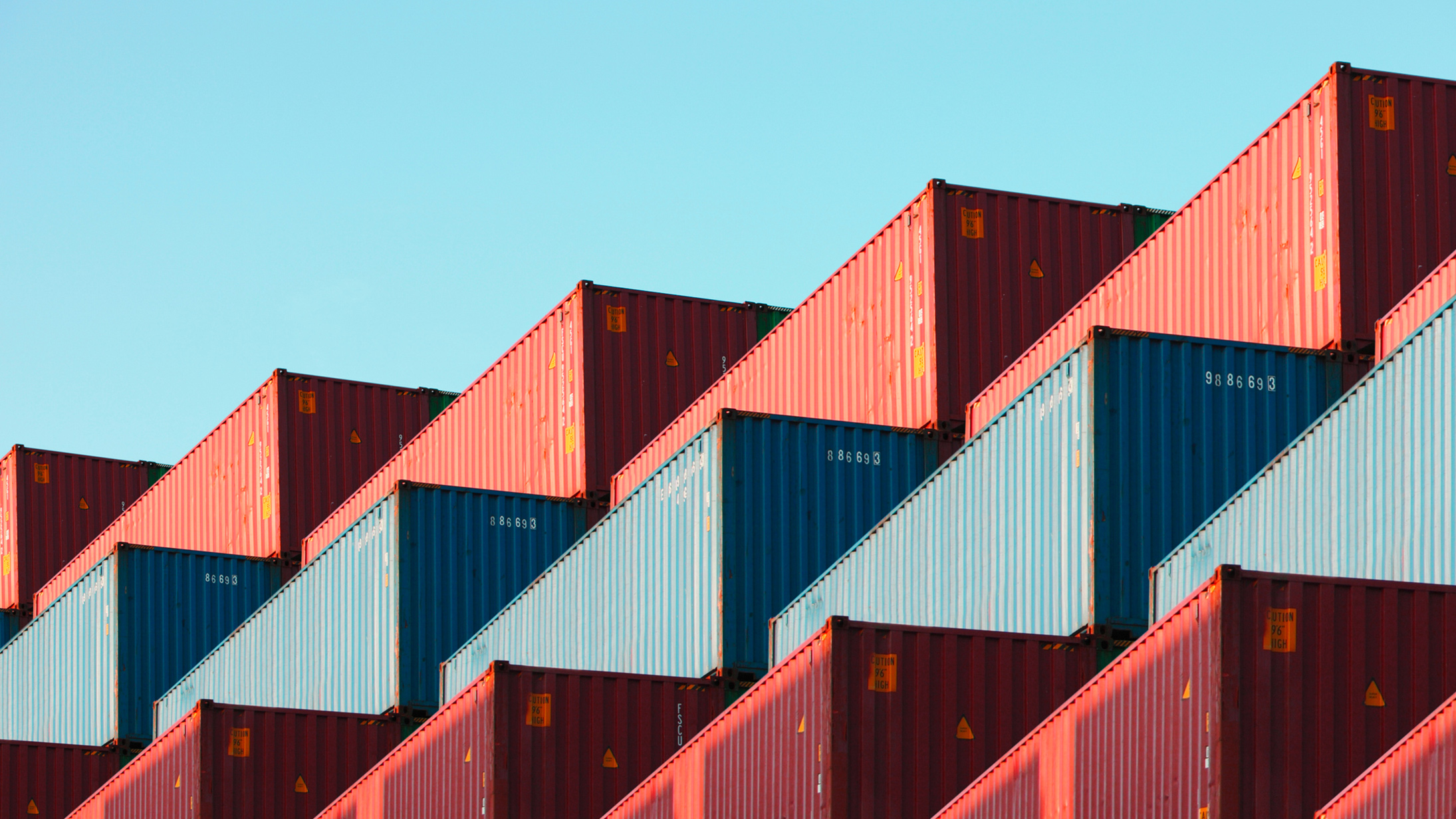

Shipping containers sit motionless at port—a sea of metal boxes painted in corporate colors that would normally be moving across oceans. Inside one is $237,000 worth of critical electronic components desperately needed for a production line in Ohio.

But they aren’t going anywhere–not until the company figures out how to handle the unexpected 25 percent tariff increase that blindsided their procurement team.

"Just absorb it," the head of sales had initially suggested, not understanding that the already-thin margins on their consumer electronics line couldn't sustain such a hit. The marketing team pushed to pass costs to consumers, oblivious to the possibility of decreased sales as a result.

Does this situation sound familiar? You're not alone.

The silent supply chain killer

Every morning, supply chain executives across the globe are waking up to similar tariff scenarios. The regulatory landscape in the U.S. has transformed almost overnight, with tariffs reemerging as the trade policy weapon of choice. Those containers aren't moving until someone makes difficult decisions with real P&L implications.

The 2018-2019 US.-China trade tensions offered a preview of what's coming. While politicians debated policy merits, supply chain teams scrambled to mitigate real operational impact. Ocean freight rates surged 70 percent as companies desperately stockpiled inventory before tariff implementation dates. Procurement teams watched helplessly as carefully negotiated cost structures imploded.

Remember that $40 toaster oven your company manufactures? With new tariff structures, the retail price jumps to nearly $52. Consumer behavior studies suggest this threshold triggers purchasing hesitation, potentially shrinking annual consumer spending across affected categories by $46-78 billion.

The Peterson Institute documented how the seemingly targeted 2009 Chinese tire tariff generated a 26 percent cost increase on imports while simultaneously driving a 3.2 percent price increase for domestic tires. American consumers ultimately paid $1.1 billion more–while experiencing significant job losses rather than gains.

The cost of inaction

At a recent supply chain summit, three executives—each from different industries—shared surprisingly similar responses to the current wave of tariff disruptions. All of them had taken a wait-and-see approach, hoping conditions would stabilize. Their strategy followed a familiar pattern:

- Assume tariffs are short-term

- Absorb the impact and hope margins hold

- Delay action until customer resistance to price increases sets in

- Gradually lose market share to more agile competitors

Internally, their finance teams described this as “waiting for market equilibrium.” But over time, it became clear that the lack of a proactive response came at a cost—one their boards could no longer ignore.

Five winning moves in the tariff chess game

Luckily, there are several moves for supply chain executives that don't involve sitting, waiting and absorbing the blow.

The strategic divergence between companies that thrive and merely survive through tariff shocks comes down to five distinct capabilities:

1. Network design flexibility

Definition: The ability to rapidly redirect production and sourcing across multiple pre- established locations without compromising delivery performance.

Example: An electronics manufacturer who previously built redundant sourcing options in Vietnam, Thailand and Indonesia shifted U.S.-destined supply to these channels within days of tariff announcements, while supplying the rest of the world from China. Their inflexible competitor with 93 percent China dependency watched helplessly as their cost structure imploded.

2. Scenario-based road mapping

Definition: A planning methodology that establishes specific trigger points and corresponding action plans for potential disruption scenarios.

Example: The consumer goods company that dynamically recalculated landed-cost and used Sales & Operations Planning war-gamed three distinct tariff scenarios with leadership and had mitigation plans ready to deploy. Their preemptive sourcing adjustments triggered automatically when policy signals hit predefined thresholds– weeks before competitors could react to the threat.

3. Collaborative contract structures

Definition: Commercial agreements that predetermine exactly how unexpected cost increases will be distributed across the value chain.

Example: The footwear brand that embedded tariff-sharing formulas in supplier contracts maintained continuity while competitors faced delivery disruptions. Their agreements specified exactly how cost increases would be distributed across the value chain, eliminating renegotiation delays.

4. Predictive analytics capability

Definition: The integration of external policy factors into demand forecasting models to anticipate market reactions before they occur.

Example: The kitchen appliance manufacturer whose demand forecasting algorithm incorporated tariff elasticity modeling adjusted production volumes proactively, avoiding both stockouts and excess inventory that plagued their industry.

5. Technology-enabled visibility

Definition: Real-time transparency into inventory and shipment status that enables precise, targeted interventions during disruptions.

Example: The furniture retailer whose digital transformation investments delivered real-time freight and inventory visibility understood the details of likely delayed supply from China and made instantaneous customer order promising pivots to favor key customers and expedite local production for products to make up the shortfall.

The industry-specific battlefield

Beyond these strategic imperatives, it’s important to acknowledge that tariffs impact each sector quite differently.

The consumer electronics industry stands at the forefront of global trade disruption, with recent tariff policies creating unprecedented strategic dilemmas. Apple faces fundamentally different challenges than Panasonic or Samsung. While Apple can theoretically restructure its manufacturing footprint (at enormous cost), foreign-based producers lack this flexibility. Companies that previously diversified manufacturing across multiple Asian countries to mitigate earlier trade tensions found themselves vulnerable when subsequent policies targeted these alternative hubs simultaneously.

The automotive sector presents a different paradox: the decades-old "chicken tax" on light trucks initially protected domestic manufacturers but eventually reduced competitive pressure that drove efficiency. Manufacturers today face a tough balancing act: they need to restructure their supply chains to avoid costly tariffs—often by moving production or changing suppliers—while still pushing forward on innovation, from launching new products to investing in advanced technologies. One wrong move, and cost-cutting could come at the expense of long-term competitiveness.

Global automakers have responded by creating flexible production networks that can adapt to policy changes, though their adjustment periods are longer than other industries due to complex retooling requirements and regulatory approvals.

Agricultural producers face the unique challenge of retaliatory tariffs that target their exports with surgical precision. When China imposed counter tariff on US soybeans, farmers who focused on the Chinese market saw their business model collapse as prices plummeted and stockpiles grew. Unlike manufacturers, agricultural producers are constrained by seasonal production cycles, limited shelf life of products and specialized equipment that prevents quick pivots to alternative crops. Many lack the scale and international connections to rapidly develop new export channels, and regional processing facilities designed for specific commodities create additional lock-in effects that severely limit flexibility when primary markets impose retaliatory tariffs.

The foreign manufacturer's dilemma

Foreign manufacturers also face their own unique challenges. For companies without U.S. production capability, the standard tariff mitigation playbook simply doesn't apply.

Companies like Sony, LG and Samsung can't realistically onshore production given massive infrastructure investments and regulatory hurdles.

Instead, these operations must execute better responses:

- Product specification adjustments that target favorable Harmonized Tariff Schedule classifications

- Distribution network optimization that reduces secondary cost impacts

- Advanced pricing strategies that selectively distribute tariff impacts across product portfolios

The new supply chain battleground

The most forward-thinking companies have recognized that tariffs represent not just a temporary disruption but a fundamental shift in operating reality. They've responded by embedding tariff resilience into their supply chain design.

Market leaders demonstrate this approach through their actions. Their network modeling incorporates geopolitical risk scenarios long before policy announcements become headline news. Their supplier diversification strategies prioritize tariff exposure alongside traditional risk factors like geographic concentration and financial stability. They conduct sophisticated scenario planning that anticipates multiple policy outcomes rather than reacting to announcements.

Most importantly, these companies understand that tariffs aren't simply an external tax–they're a strategic variable that must be managed through sophisticated supply chain design.

While others hope for policy stability, these organizations have built supply chains that thrive regardless of tariff environments. The difference isn't luck–it's architecture.