How to take full advantage of better decision-making power with predictive analytics and AI.

What issue can we solve for you?

Type in your prompt above or try one of these suggestions

Suggested Prompt

Is Supply Chain Decision Making Changing Forever?

Supply chain organizations make hundreds of consequential decisions every day.

- Contact planners for raw materials or hope that they arrive on time?

- Request additional labor to guarantee shipping schedule or wait and see?

- Expedite shipping at a higher cost or risk disappointing customers?

These decisions are difficult. They happen fast with no time to assess and reflect. With data in multiple systems that aren’t always reliable, the full picture is unclear. And these decisions have high stakes. They are tied to the very purpose of the business: selling products to customers. The bottom line? Supply chain managers are overwhelmed and need the right tools today to enable faster, accurate and more real-time decision making.

From gut checks to guided choices: Supply chain decision-making enters its next era

There’s been an evolution in supply chain decision making over the last two decades. The more digitally mature your organization is, the less likely your people will be sweating over spreadsheets. Instead, decisions are increasingly being made based on insights from analytics, algorithms and statistical methods. But a fundamental question remains. How can our decision-making be better than before?

The good news? Advancements in analytics and AI are changing the game.

95 percent of supply chain organizations have boosted investments in analytics.

Top performing supply chain organizations use AI to optimize processes at twice the rate of low performers.

This evolution isn’t over. In fact, it’s getting faster. Analytics is key to this momentum. So is AI. It’s helping to speed up the rate of change and scope of impact.

By improving analytics and AI maturity, you can transform the decision-making process—getting deeper insights into the who, what, when, why and how of the issues you face. With maturity, expect more computer-aided decision making with humans in the loop. Changes won’t happen overnight, and there’s no easy button. Read on for how to prepare your organization to make the most of this opportunity.

Understand the four stages of analytics maturity—and how each unlocks smarter, faster decisions

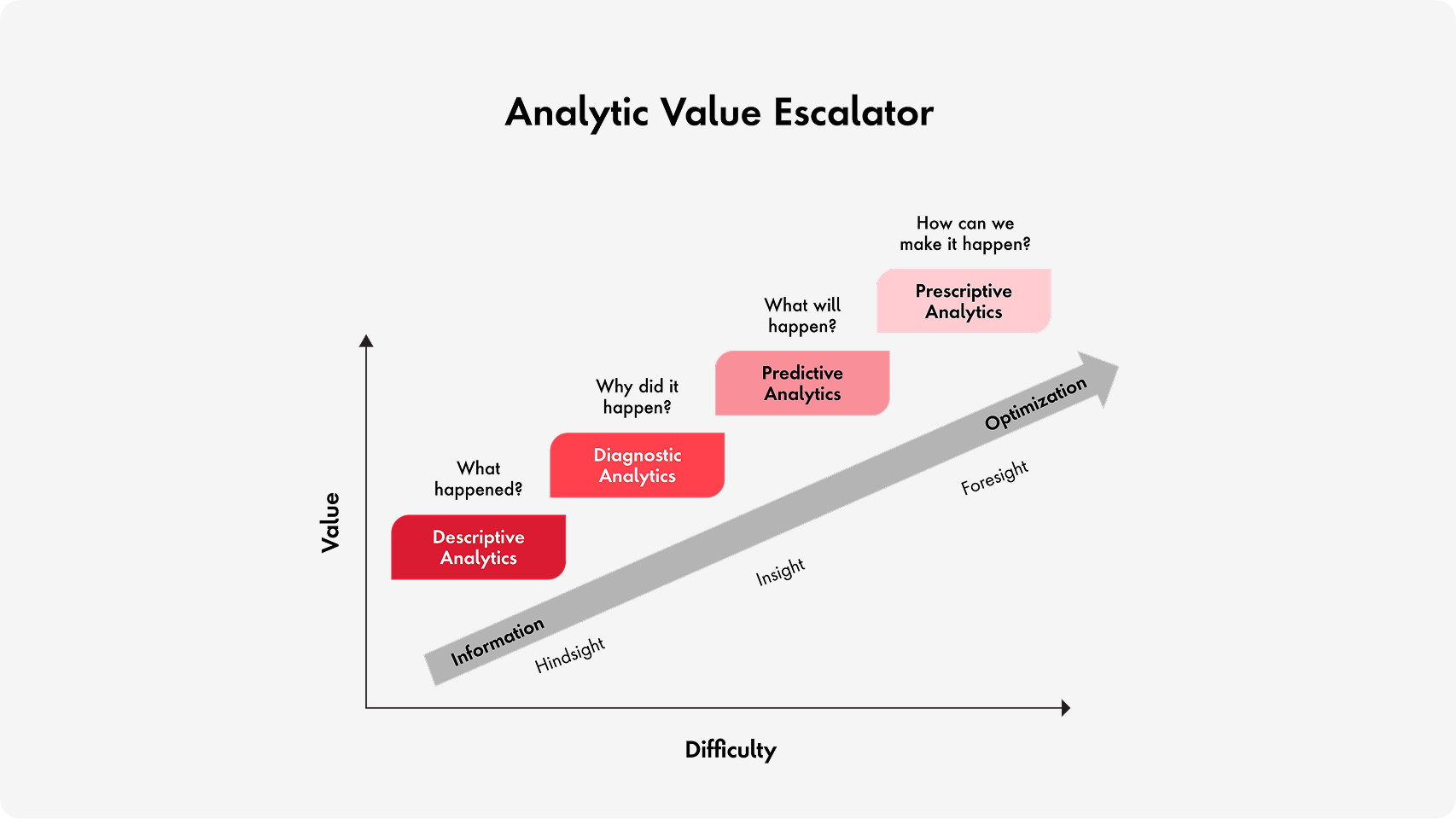

Understanding where you can go with analytics and AI in supply chain decision-making requires an honest look at where you are. Analytics isn’t a monolith. It’s a set of capabilities along a maturity curve that moves decision making from understanding what happened to making something you want to happen—from hindsight to foresight (Figure 1). The maturity curve includes the following:

Figure 1: Analytics maturity curve

Self-assessment

Where is your organization on the analytics maturity curve?

Descriptive analytics is rear-view window insight. Use dashboards to aggregate and filter historical data in relevant ways.

Diagnostic analytics identifies process exceptions and data that point to failure mode. Zero in on what orders are at risk and why. Compare actual lead times with planning system data.

Predictive analytics predicts a future state of the supply chain and is often AI-powered. Create demand forecasts for new products. Predict lead times between facilities. Plan port logistics based on congestion or weather. Enable proactive maintenance on sorting machines in a distribution center.

Prescriptive analytics is AI suggesting actions to address a situation. Case in point: Your planning system raised 500 exceptions today like it did yesterday and the day before. Understand which are important. Know what has changed. If the problems are related to a late delivery from a supplier, get insight on whether to report it now or ship from a different facility. Assess if and when it’s time to raise an NDA non-compliance or reset inventory levels.

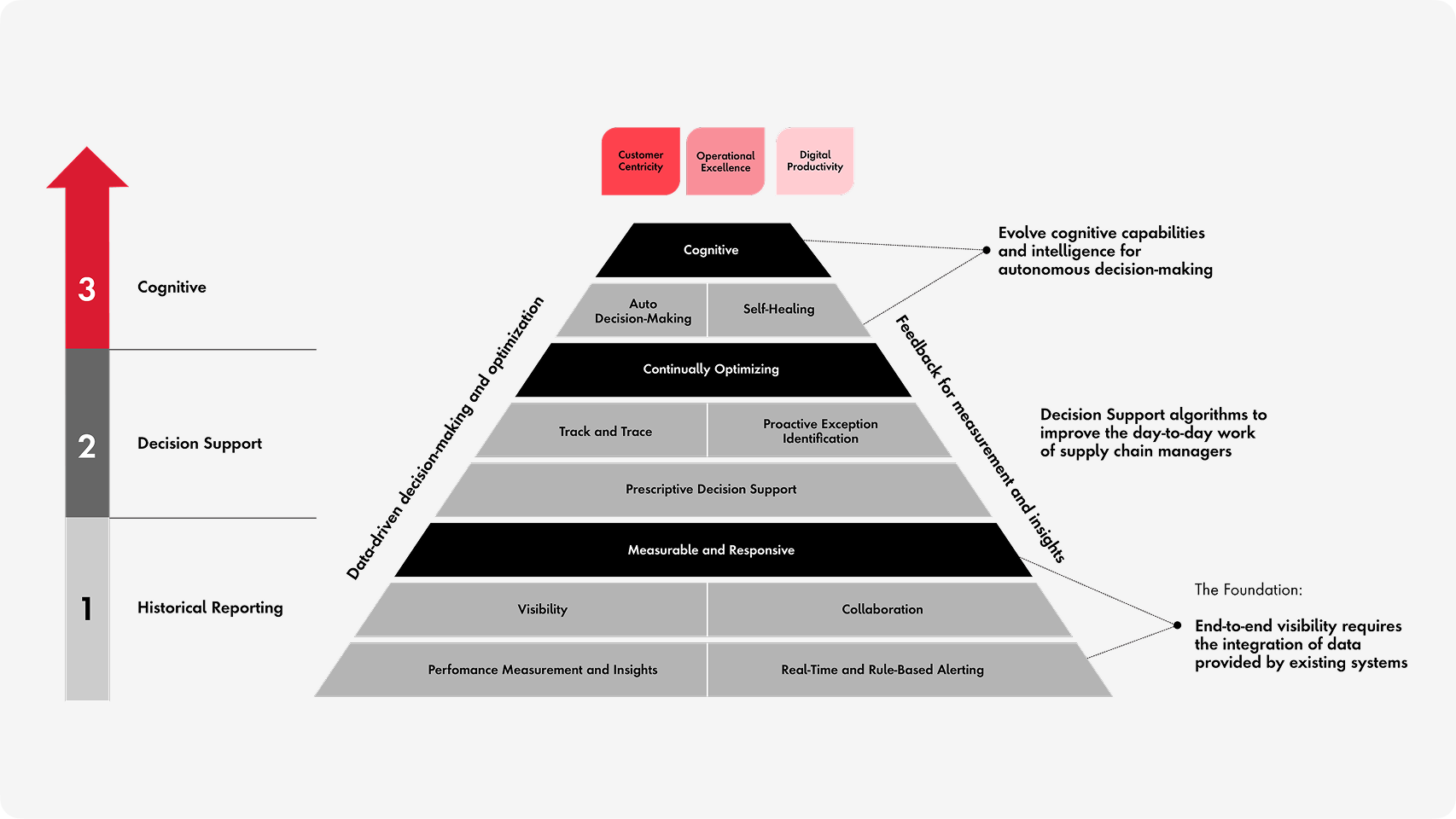

As you move up this analytics maturity curve, your organization gets more sophisticated in its data-driven decision making—both in how decisions are made and in who makes them (Figure 2).

Figure 2: Decision-making maturity curve

Self-assessment

Where is your organization on the decision-making maturity curve?

The first phase of this decision-making maturity curve is essentially what supply chain organizations have done for years: making decisions based on previous patterns and outcomes from historical reporting. This is extremely limiting given that the past rarely repeats itself. As you expand decision support capabilities, you move to the next phase, using analytics and modeling to make strategic and tactical decisions with a focus on continuous improvement and optimization.

In the cognitive phase—which is still largely aspirational—automated insights and AI-generated recommendations enhance decision making. Humans remain in the loop. They just have different roles. AI proposes; humans approve. AI decides; humans guide. AI self-adjusts; humans steer the strategy.

Inside the organizations turning AI into a real supply chain advantage

While most organizations haven’t reached this phase, there are standouts using AI and advanced analytics for faster, more accurate supply chain decisions.

To boost decision making with AI and advanced analytics, be intentional about driving change. As with any organizational transformation, success here hinges on getting the fundamentals right:

- People: Strong executive leadership, buy-in from your team and collaboration between business and IT are non-negotiables.

- Process: Because of the relationship between technology and processes, technology implementation projects can involve reorganizing your company’s processes.

- Policy: A clear, consistent policy backbone is key to support your performance objectives.

- Metrics: You should have a tangible CFO-approved way to measure ROI for your projects.

- Technology: You need the right tech tools to enable more effective supply chain decision making.

But don’t stop at these fundamentals. There is more work to do in order to create a strong organizational foundation for moving up the decision-making maturity curve.

Everyone copies from SAP into Excel—AI agents won’t change that unless you fix the trust gap

Who doesn’t know the old garbage-in garbage-out principle? If your data is bad, so goes everything else. You know the reality. The lack of a single source of truth is a massive liability. There are so many silos. So many systems. Different systems tell different stories. TMS versus ERP versus warehouse management systems (WMS): which is right?

It’s the business users who’ve learned the hard way what data to trust. If you’re asked to analyze inventory levels and turnover rates based on an SAP report, but managers point you to a spreadsheet instead, that’s your sign that the information in the report is insufficient, or completely wrong.

Relying on workarounds to get good data is no way to make supply chain decisions. To address this issue, many organizations started creating data lakes. However, some got burned because it took so long to deliver value. Instead, strike the right balance between reaching momentum with low-hanging-fruit projects and establishing a data-lake roadmap. While counterintuitive, think of use cases as minimum viable products (MVPs). Sometimes you can build a use case from reliable spreadsheet data. Once business users are satisfied with the new report or user interface, then you can focus on automation and a data lake.

On the horizon: Could AI agents replace data lakes?

There’s a lot of talk about AI agents for supply chain decision making. It’s clear why. These agents can navigate organizational

and external systems, stitching together all the necessary data to enhance decision making. They can act as a single user interface

that integrates relevant information, democratizing data access in the process. AI agents can start providing descriptive information,

and they can easily be extended to provide predictive and prescriptive information. While AI agents won’t replace data lakes—at

least in the short term—you may not need a data lake to benefit from some of their capabilities.

If your IT center of excellence doesn’t include the business, it’s not excellent

Many organizations turn to centers of excellence to develop analytics and AI expertise for the business. This makes sense, particularly if you execute it in a “land and expand” approach. However, be sure to avoid a common trap that could create headaches you don’t need.

In many organizations, IT owns investments in analytics and AI, and business and functional interests are not represented in the center of excellence. This creates a messy “them versus us” dynamic where the CIO and the COO organizations are misaligned. The result? Systems that, at best, don’t work as needed, and, at worst, simply aren’t used.

To avoid this situation, break down barriers between business and IT. Appoint a cross-functional executive team to oversee projects and create individual incentives connected to project outcomes. Put together an execution squad of different subject matter experts. It’s critical to include supply chain experts who understand how your processes map to your systems. There must be data engineers dedicated to data ingestion and quality control. They report to a data architect who oversees data governance. It’s also essential to have data scientists who are responsible for algorithm training, feature selection and model lifetime management. User interface engineers maximize the user experience, which can be key to whether or not decision-making tools get used.

The hardest part isn’t the tech—it’s getting people to trust it

The great irony of tech-powered transformation like this is that the technology itself is rarely the biggest hurdle. Organizations typically struggle the most with internal politics and consensus building. This is why cultivating trust in the data, algorithms and supply chain decision-making tools is as much about the people as it is the technology change.

One way to build trust is with an iterative approach modelled after the “try-learn-adapt” spirit of resourceful entrepreneurs. They intentionally launch a basic product with just enough features to satisfy early adopters so they can refine it with real-world feedback. Put simply, start small. Quick wins with business and technology stakeholders—and even with your own team—create momentum you can build on.

Big transformations don’t start big—they start with a pilot that proves its worth

Imagine a manufacturing company managing hundreds of product formulations across multiple production sites. Leaders identified a high-impact, low-risk opportunity: optimizing how raw materials are mixed across a small number of production lines. The process was complex, with too many variables for manual planning—but ripe for analytics.

They used a hybrid approach: one tool quickly narrowed down the top scenarios, and another refined them into precise, actionable recommendations. Rather than rolling this out company-wide, the team ran a pilot on just one set of lines. Business users were brought in early to test the model, flag usability issues and shape the outputs.

Within weeks, the team saw measurable improvements: fewer production delays, reduced material waste and clearer planning cycles. Most importantly, the early success created organizational buy-in and enthusiasm to expand analytics into other parts of the supply chain—creating a flywheel of value-driven adoption.

Where data flows, advantage follows

If you lay the right foundation to take full advantage of analytics and AI, you can make supply chain decision making faster, more accurate—and an even greater competitive asset.

Imagine being proactive, not reactive. Imagine automated reports that proactively indicate anomalies in your processes and provide suggestions based on how you addressed those anomalies in the past. Imagine this and more—getting insights to design better products, delight customers and leave competitors in the dust. Just like that, the supply chain becomes a value chain.

Ready to evolve your supply chain decision-making maturity? Learn more about Publicis Sapient’s supply chain analytics and AI solutions.