What issue can we solve for you?

Type in your prompt above or try one of these suggestions

Suggested Prompt

Insight

COVID-19: What’s Next for Food Supply Chains?

COVID-19: What’s Next for Food Supply Chains?

This article is part of a series on long-term strategies industries and sectors can take in response to COVID-19.

As COVID-19 continues to impact every aspect of society, the global food supply chain is being squeezed even tighter than it was before the pandemic hit.

Ecosystems are under tremendous stress to cater to an increasing world population. Urbanization, economic inequality, geopolitical conflicts and climate change are further disturbing the ecosystem and emerging diseases with long, indefinite durations that are not just a growing risk but perhaps the new normal as pressures from food shortages increase.

Billions of people are now aware of the dangerous reality of zoonosis — the ability of pathogens, including bacteria and viruses, to enter the human population from an animal host as was the case with COVID-19. Zoonosis isn’t a novel problem given HIV originating from chimpanzees, Ebola and Marburg from bats and swine and avian flu from pigs and birds, but given the uncontrollable global spread of COVID-19 and its direct impact on the food supply chain, many organizations including agriculture and meat businesses, as well as consumers, are severely concerned.

“Agribusinesses must acknowledge the fact that new diseases are emerging with the potential to spread rapidly across the globe, and this will be an inevitable part of our future,” said Sidhartha Bhandari, Director, Program Management. “Positioning organizations to proactively build and sustain business operations under such eventualities must be factored into business strategy and ways of working.”

While the fundamentals in the Farm to Table chart pictured here remain largely the same for crops and livestock alike, in the long-term the social, economic, geographical and regulatory changes will force organizations operating in this space to rethink their strategy for sustaining their businesses during unpredictable times.

Here are the shifts in thinking that must be considered as businesses within the food supply chain look to evolve their strategies in light of the recent pandemic escalations:

Redesigning Food Supply Chains

Our global food supply chain design is predicated on the assumption that commodities can flow freely globally. This allows products to be sourced, produced and distributed at low cost anywhere in the world. As a large part of the world goes into self-isolation and quarantine, pandemics like COVID-19 are highlighting the vulnerability in this model and the need for redesigning the food supply chain.

Our current supply chains are set up with supply and demand centers spread far apart across the globe with the flow of commodities often getting blocked during pandemic situations.

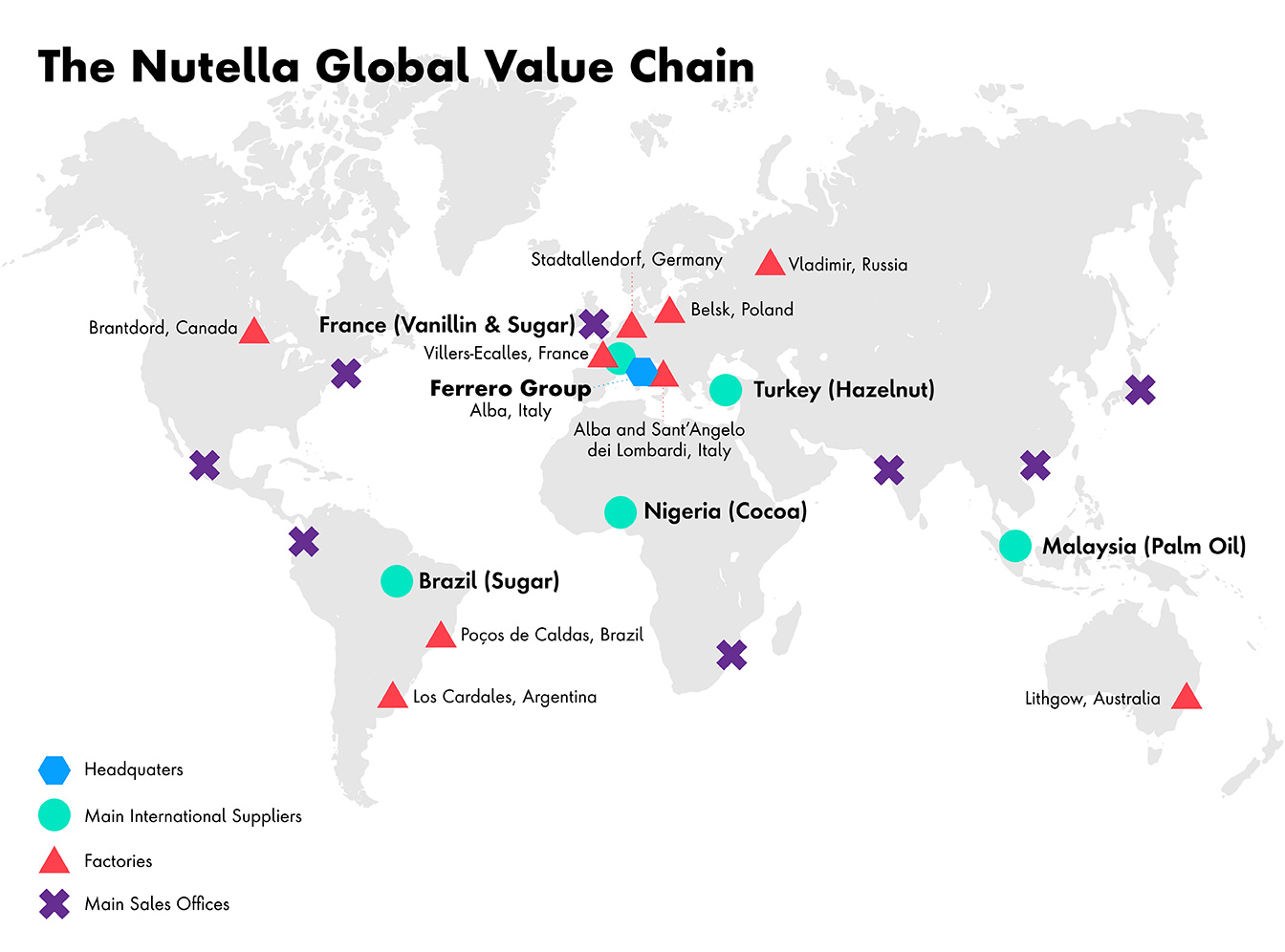

Nutella, for example, demonstrates the complexity involved in redesigning supply chains. It’s estimated that nearly 360,000 tons of the product are consumed annually across 160 countries and in each 13 oz. jar there are more than 50 hazelnuts used, requiring Nutella to consume more than 70 million tons of hazelnuts each day. For Nutella, the hazelnuts come from Turkey, cocoa from Nigeria, palm oil from Malaysia, sugar from Brazil and Europe and the vanilla flavor from China. Some nine production factories around the world bring all the ingredients together to make the final product.

With restrictions on the global movement of people, commodities and services, and containment measures such as lockdowns, organizations like Nutella may be forced to either relocate, close production plants or rapidly make changes to their supply chain in order to source from alternatives for unknown periods of time. This could mean sourcing ingredients locally or developing a secondary global source.

Image source: Researchgate, Ferrero, Sourcap and various online sources.

“In such a business landscape marred by trade wars, geopolitical unrest and a pandemic like COVID-19, a new kind of design thinking is needed that enables companies to reconfigure their supply chains and be ultra-agile and responsive to rapidly changing global trade policies, supply dynamics and disruptions,” said Bhandari.

While there are many aspects to evaluate when considering how to redesign supply chains, the application of innovative digital solutions in this space can certainly expedite the realization of next-generation, digitally integrated supply chains.

Digitizing Supply Chains

Agribusinesses have come a long way in the application of technology to improve ways of working within the food supply chain during the last 20 years. Blockchain, for example, is gaining traction in food supply chains for the security and transparency it provides to each actor involved. Despite this progress, digitization has been occurring in pockets, leaving large parts of the business digitally disconnected or still heavily reliant on high-touch, manual business processes.

With the largest work-from-home experiment in human history currently underway, these gaps in our ability to be digitally connected to food supply chains have become even more acute – from contracting to sourcing, commodity weight management to quality inspections, and real-time commodity movement tracking to payments and settlements.

Companies like Tri–States Grain Conditioning, Inc., for example, are working on digital grains monitoring within storage bins or silos to collect real-time temperature and moisture monitoring, an important factor in ensuring the grain and seed are in great condition until it’s time to sell.

Terrabee has also created solutions such as sensing technology that uses cameras and the Internet of Things to perform real-time stock level inventory tracking and facility intrusion detection.

These examples remain exceptions as there still aren’t many digitally integrated solutions for silo storage health. “A connected view of this information is absolutely crucial especially during pandemic emergencies,” said Bhandari. “From a farmer’s perspective, it’s about ensuring safe storage of grains to ensure minimal waste, contamination and that throughput is delivered. For governments or other businesses buying these commodities, it’s key to understand where and how the grains were stored to make informed decisions as part of their sourcing strategies.”

Agribusiness leaders must invest in building digitally connected and ultra-agile food supply chains that are rapidly able to adjust to market disruptions including pandemics like COVID-19. For agribusiness organizations operating within the food supply chain, re-imagining the overall supply chain design is now fundamentally important to ensuring an expanding global population will be able to meet its dietary and nutritional needs for generations to come.

Related Reading

-

![]()

Getting Ahead With New E-trends

E-commerce moves fast, but you can move with it. This article highlights some of the latest trends to help you plan and prepare.

-

![]()

Ag Retailers Guide to E-commerce

How to create an e-commerce platform that complements existing agribusiness sales channels.

-

![]()

Why B2C E-commerce Should Shape Agribusiness

As demand moves from offline to online, how does agribusiness need to change in order to succeed?